Mechanically Jointed Rodless Cylinders

| ・With 5 standardized guide types ・A variety of applications are available based on the load mass and required accuracy. |

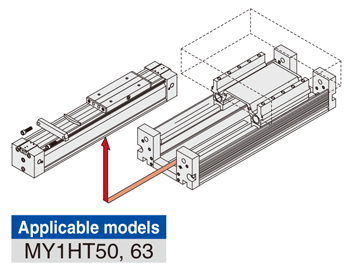

| Type | Series | Action | Bore size (mm) |

|---|---|---|---|

| Basic | MY1B | Double acting | 10,16,20,25,32,40,50,63,80,100 |

| Slide bearing | MY1M | Double acting | 16,20,25,32,40,50,63 |

| Cam follower guide | MY1C | Double acting | 16,20,25,32,40,50,63 |

| Linear guide | MY1H | Double acting | 10,16,20,25,32,40 |

| Linear guide | MY1HT | Double acting | 50,63 |

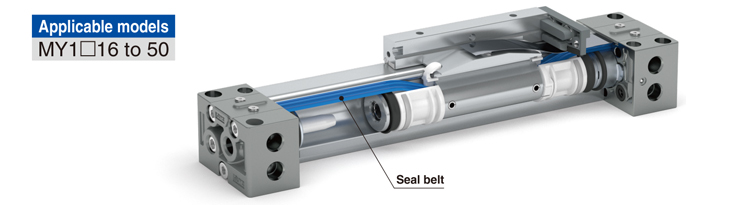

The flexible material of the seal belt allows for improved adherence to the cylinder tube, resulting in a reduced leakage amount.

(50% reduction compared with the current product)

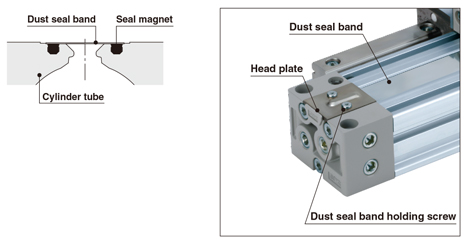

The seal magnet on the cylinder tube adsorbs the dust seal band with magnetic force, resulting in improved holding force.

The dust seal band can be easily removed for replacement by simply loosening the two holding screws.

Easier maintenance

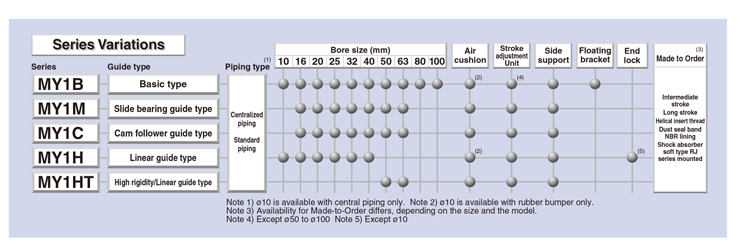

With the same outer dimensions and workpiece mounting dimensions, both series are compatible with stroke adjustment units, side supports, auto switches, etc.

Improved safety and accuracy of the entire system can be achieved by storing auto switch lead wires in the product's designated lead wire containment grooves.

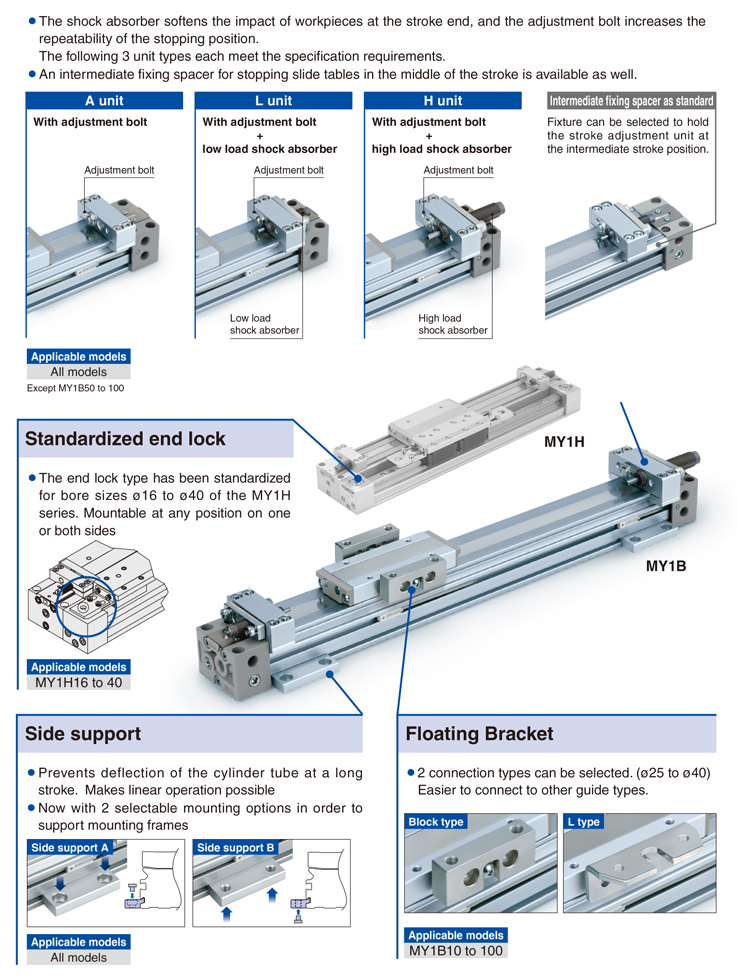

Auto switches can be mounted from the front at any position on the mounting groove.

It is possible to replace cylinders with a workpiece being mounted.

The cylinder body can be secured directly from either the top or bottom without the use of mounting brackets. This does not change the overall length dimension.

Mechanically Jointed Rodless Cylinder MY1

- Product Code: MY1 Mechanically Jointed Rodless Cylinder

- Availability: In Stock